When you make purchases through links on this site, The Track Ahead may earn an affiliate commission. Also, these posts are based off my own experiences. I am not responsible for any action you take as a result of reading this. Learn More

I’ve lived with bare concrete flooring in my garage at different residences for as long as I can remember. There’s nothing wrong with having bare concrete on the floor of your garage, it’s durable, looks okay, and cleans up easily for mild spills. However, we recently moved into a new home and now have a 3-car garage space to work with. Because it’s so much harder to do any renovations with your garage floor after you move in, we took this opportunity while nothing was moved in yet, to get the floor coated before we moved in.

Garage Flooring Options

There are a number of options available for garage flooring such as stick-on vinyl tiles, interlocking tiles, and floor coatings. I’ve heard a lot of the good and bad things for all of these options, but in my opinion, the option that combines the best looks with the most durability is an epoxy floor with a polyaspartic topcoat. This is the option we ultimately went with, but I will go over the various options below to better inform you of the various options.

Floor Coating Types

DIY Epoxy Flooring

Something to decide on if you’re planning to go the epoxy floor route is whether to do the epoxy flooring yourself or have a professional installer do it. I generally like to do as much home improvement myself, however there were a few reasons I chose not to with epoxy flooring. The first reason was simply because we haven’t moved in yet and I was too far away to do this work while we were also busy dealing with moving.

The second reason I did not do it myself was because I have always heard that DIY epoxy floorings almost always peel up after a few years of use. I don’t believe that this always due to the installation (e.g. inadequate prep or improper installation technique) but more so that the epoxy material you buy at your local home improvement store just doesn’t compare to the industrial strength coatings that are used by professionals.

From what I’ve heard, the DIY garage floor coating kits are usually made up of a low amount of solids and are water-based, so they just aren’t as durable as professional grade coatings (which would be oil-based and have a higher percentage or 100% solids.) Now, there are some industrial grade coatings that are being sold on Amazon as professional grade, so that might be an option if you truly want to do it yourself.

Epoxy, Polyaspartic, Polyeurea, Polyaspartic? What are all of these things?

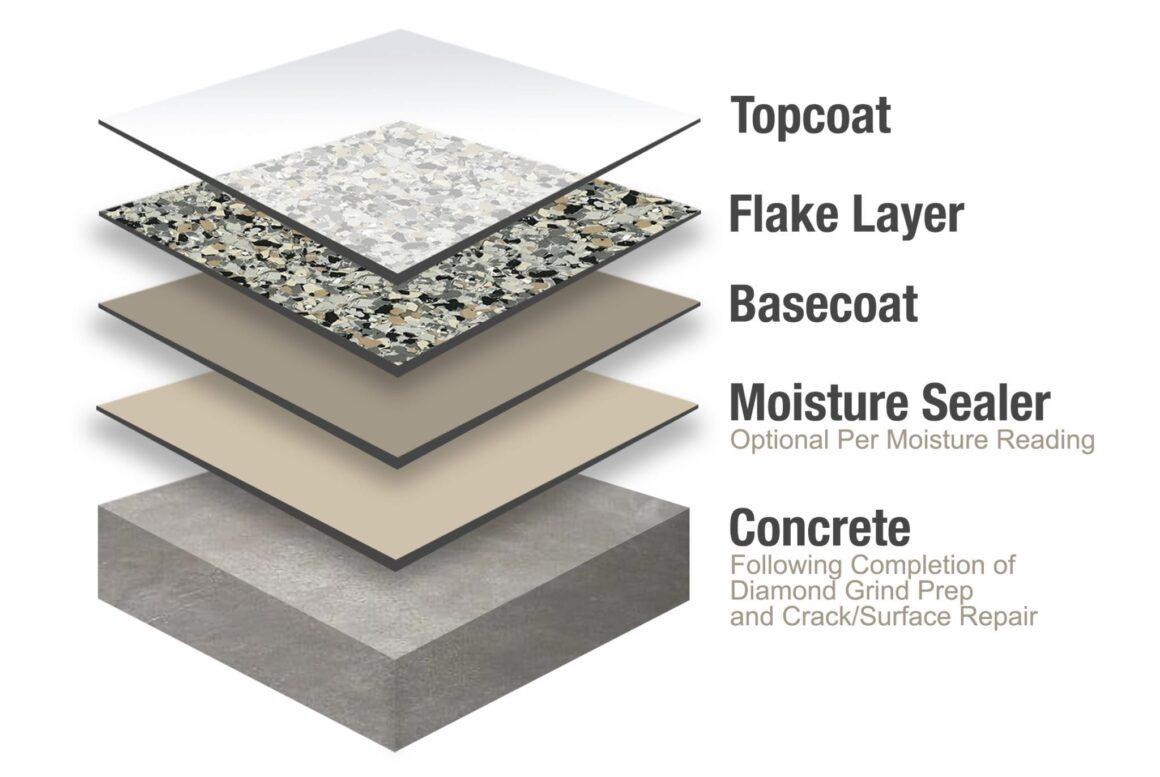

People tend to use the term epoxy coatings pretty loosely, to mean any of the different types of floor coatings out there. To start off, let’s talk about epoxy coatings. They are quite popular, but they have some drawbacks. An epoxy flooring is a two-part system made of hard resin. The result is a smooth and durable finish that is resistant to spills and wear-and-tear, although it might crack from a concentrated impact (e.g. a falling sharp object.)

Epoxy coatings can be applied as a bottom layer, as well as a top layer. Over time, epoxy coatings are known to turn yellow depending on how much UV exposure it gets. Doing an epoxy coating is generally a 2-day job where the first day involves prep, applying epoxy primer, and broadcasting flakes (if desired.) The second day is spent removing excess flakes and applying a top layer of epoxy coating.

Another option is to apply a polyaspartic coating both as a bottom and top layer. Polyaspartic is a type of polyurea (a subgroup of polyeurethanes.) The benefits to a purely polyaspart coating over an epoxy coating is the improved durability, but more importantly because it cures so much quicker than epoxy, it can be a 1-day job instead of 2.

The cons of using polyaspartic over epoxy is the higher cost, quicker set time (which means you really need someone with experience doing this), and if you don’t prep the concrete surface properly or the concrete has high porosity it may not adhere very well.

I’m aware that there are other garage coating types although the most common ones you’ll hear about are epoxy and polyaspartic, which is why I am discussing those choices here.

Finally, you can opt for a combination of an epoxy primer (bottom layer) and a polyaspartic coating (top layer.) Doing this still leaves you with a 2-day job, but the benefit of doing this is that you minimize the chance of yellowing epoxy. This is because the exposed layer to UV light is the polyaspartic topcoat.

Especially if you broadcast flakes to rejection (meaning you have 100% coverage with flakes over the underlying layer of epoxy), then you won’t have any epoxy that is exposed to UV light. The other benefit of this combination is that epoxy as a primer layer adheres better to the concrete than polyaspartic.

Things to Consider When Getting An Epoxy Flooring

First, you’ll choose the color of the coating and the color of the flakes. There are all sorts of colors to select from, but you’ll need to make that choice with your garage floor coating installer, since the color availability will depend on the product that they use.

The second thing to consider is the brand of coating they are using. Many contractors will have their preferred type of coating to install, brand to use, and product (with varying percentage of solids) to install. A higher number of solids is generally better because less product evaporates into the air, leaving you with a stronger floor in the end. However, the downsides is that it is a bit more difficult in install and costs more.

Finally, a popular topic that is hotly debated is the amount of flakes you should apply to your floor. The most common thing you will hear is, “don’t use flakes because if you ever drop a bolt, you’ll never find it!” Go to any garage forum online and you’ll see this mentioned over and over again. I suppose this could be the case where you might lose small parts on the floor of your garage, but I don’t know if this is a good enough reason for not putting down flakes.

The reason why flakes are installed are mainly for looks. You can’t deny that flakes on a floor coating is a beautiful sight to see. In addition to making your garage floor look amazing, it also hides a lot of imperfections of the concrete floor. From what I’ve heard, if you do an epoxy flooring and don’t put down any flakes, you will see every little imperfection in your floor and it will look terrible.

Another reason why a full coverage of flakes (broadcast to rejection) is ideal is because if you don’t completely cover your epoxy coating, the epoxy underneath is prone to yellowing from exposure to UV rays over time.

What Garage Floor Coating We Ended Up Going With

We shopped around some local garage flooring contractors and ended up going with TS Flooring located in Rancho Cucamonga, California. We chose a 100% solids epoxy (bottom layer) and a 88% solids (polyaspartic top layer) flooring produced by Onyx Concrete Coatings, with a light grey color broadcast to rejection. They completed the job in two days as promised.

We did have some issues with TS Flooring as they were quite rude and reluctant to come back out to fix a rough patch in the floor. Eventually they did come back out to smooth out the rough spot.

Aside from some of those customer service issues, the floor came out pretty nice. More importantly, the floor was finally finished and that allowed us to move in and start renovating the rest of the garage! I think the color is a really nice and I love the feel of the floor even when I’m walking around the garage without shoes on. The floor doesn’t feel cold as if you were walking on bare concrete, and it is super easy to sweep and clean the floor.

Now with the garage floor coating complete, we can move forward with prepping the existing walls for paint, installing insulation and drywall on the unfinished walls, putting in electrical, and doing the finishing touches. I’ll be posting more on the progress on the garage and hopefully providing you with more helpful information should you decide to remodel your garage space as well.