When you make purchases through links on this site, The Track Ahead may earn an affiliate commission. Also, these posts are based off my own experiences. I am not responsible for any action you take as a result of reading this. Learn More

If you own a truck and actually intend to use it as a truck, you’ve probably thought about how you’d want to protect the bed of your truck. You might have just bought a new truck and want to protect the paint surface of your bed, or you have an existing bed liner that is worn, or you just simply want a new bed liner. There’s several options out there and it’s important to understand what the pros and cons of these options are, and choosing the best one that fits your needs and your budget.

Types of Truck Bed Liners

There are a variety of different bed liners available with varying positives and negatives with each option. It’s important to understand the different options available to you before you can make an informed decision on which one to go with.

Drop-in Bed Liners

Drop in bed liners are made out of plastic and it drops right into the bed of the truck. The plastic liner comes pre-formed, and usually comes in two pieces, one large 4-sided piece for the bed of the truck, and another piece that attaches to the tailgate. The price is economical ranging typically between $200-$300 for the drop-in bed liner.

The good thing about a plastic drop-in liner is that it is actually quite durable and does an excellent job of protecting the bed of your truck. If you look at the texture of the plastic liner, it is not flat. In fact, it has a ribbed texture that is ideal for absorbing the impact of dropping heavy or blunt objects into the truck bed. If you’re looking for a bed liner that can take a beating and is fairly cheap, this is the way to go. If you look at most contractors’ truck beds, they will typically use a plastic drop-in liner. This is due to the fact that it is low cost while still being able to take a beating.

The downside to a plastic bed liner is what might be happening underneath. Specifically it is what’s happening between the plastic liner and the actual bed of the truck. Keep in mind that the bed liner and truck bed are not really monolithic in that they are not held molded together, nor are they held securely enough to each other to prevent one from rubbing against the other. If you look at a cross section, you’ll see that there is a slight gap between the truck bed and the drop-in bed liner where leaves, debris, and water can get trapped.

If you were to pull off a bed liner after years of use, you will likely see numerous scratches of the clear coat and even of the paint under the bed liner. If you wait even longer, you’ll likely see some significant paint damage behind the plastic bed liner especially on the floor of the bed. What accelerates this corrosive process is the accumulation of leaves, debris, and water that gets trapped between the truck bed and the drop-in bed liner. Since it has nowhere to go, it stays stagnant and continues to corrode the truck bed.

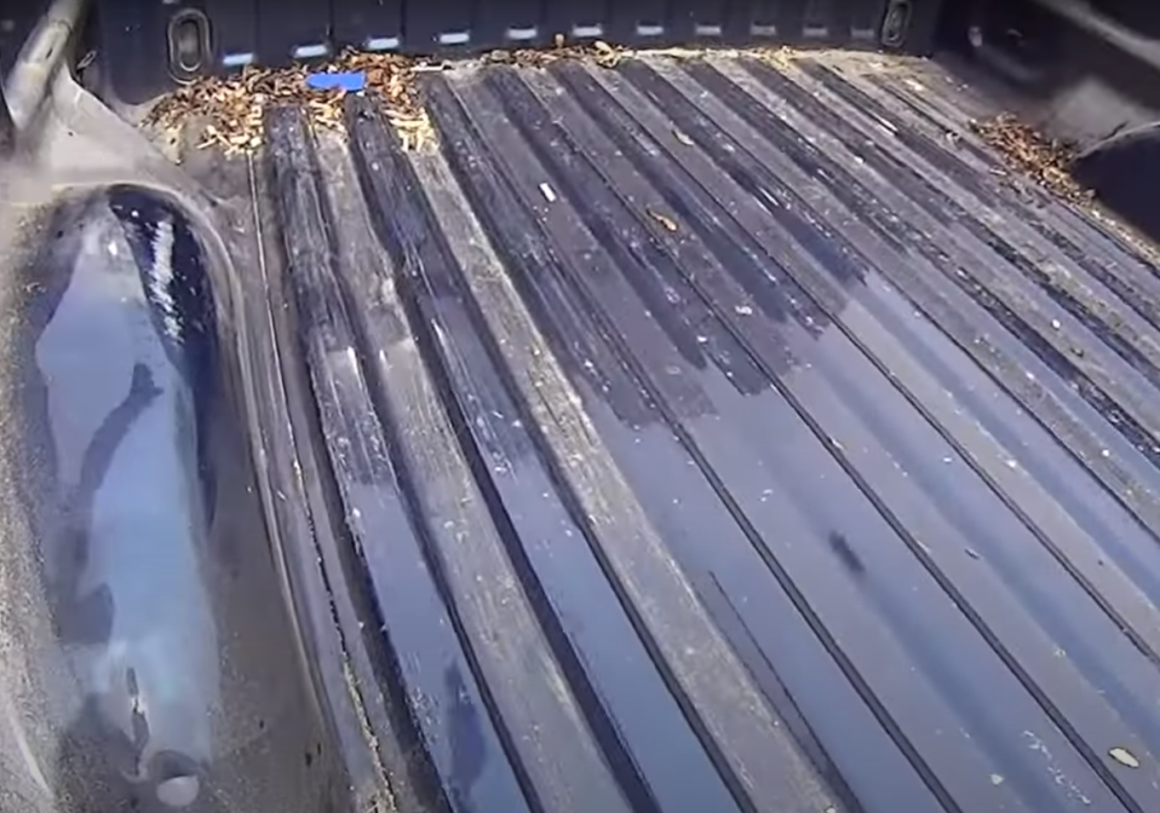

The above image is an example of what a truck bed might look like with the plastic drop-in liner removed after several years of use. Plenty of leaves and debris are trapped under the liner, but it doesn’t necessarily mean that it has completely corroded through the clear coat or paint. However it is apparent that there are numerous scratches with the likelihood of some beginning stages of corrosion.

Spray-in Bed Liners

Spray-in bed liners generally cost a lot more than a drop-in bed liner especially if you are having a specialized shop handle it. In my opinion, spray-in liners is the best looking option when choosing truck bed protection. In order for a spray-in bed liner to be done, the entire bed of the vehicle will need its clear coat scuffed up in order for the spray-in liner to adhere properly to the surface. The spray-in bed liner is then, as the name suggests, sprayed in. Depending on which company you go with, the cost can range from medium to high, but typically going to a shop for a spray-in liner will cost a good chunk of change.

Spray-in liners such as ones that are offered are usually made of Polyurea, polyurethane, or a hybrid of both. Polyurea is like a polyurethane in that it starts with the same isocyanate compound, but the difference is that it reacts differently to create the final product. The advantages of polyurea or a polyurea blend over a traditional polyurethane is that is is more resistant to lower and higher temperatures, has almost no maintenance needed, and has no VOC’s and therefore no odor. It also cures faster than polyurethane and has stronger properties such as tensile strength, elongation, tear strength, hardness, etc.

These factors along with common characteristics of being extremely durable, flexible, and resistant to stains/oil, make this the ideal product for lining a truck bed.

Keep in mind that spray-in bed liners are extremely durable to abrasion and more spread out impact forces, but it will not resist gouging or tearing from any localized impact such as a with a sharp object. Warranties that are typically offered towards installation defects and are usually limited to defects such as cracking, bubbling, or flaking.

When choosing a spray-in bed liner, you should determine if you need UV protection or not. Without the UV protection, the bed liner will dull over time and will not look new after many years of sun exposure. If your spray-in bed liner has UV protection, then it should not dull over time and will have that glossy look even after some time even with sun exposure. If you are planning to install a tonneau cover or you don’t care about matte look of the liner years down the road, then the added UV protection may not be necessary.

The cost of spray-in bed liners are typically higher than other bed liners as there is cost involved with specialized equipment and training with having a dedicated shop perform the install. At this price point, there are additional options that may provide more even more durable polyurea finishes (and even colored tints) that make an already pricey spray-in bed liner even more expensive.

What to Expect

If you have a specialized shop take care of your spray-in liner, an appointment will normally need to be made. You will usually have to drop off the vehicle for several hours or longer depending on the type of spray-on liner you choose. Cure time on spray-in liners are typically very quick so the liner may actually be dry to the touch when you pick up your truck. However, it is advised to give it at least a day to fully cure before any heavy use.

Preparation for Spray-in Liner

Prior to the spray-in bed liner, the entire truck bed surface will need to be surface prepped. This means scuffing up all surfaces with sandpaper or sanding discs to ensure there is a good rough surface for the spray-in liner to adhere to. The sanding is typically done with 80 grit sandpaper, and the scuffing should only be done to the clear coat; never sanding down into the base coat of the paint.

A shop that handles spray-in liners should have the experience to properly prepare a truck for a spray-in liner. This includes using wire tape to get a clean edge along the borders, as well as covering holes and fully protecting the rest of the vehicle to prevent any overspray from the spray-in liner material. If you chose to spray the liner yourself, this is a part of it that requires the necessary experience and equipment/materials to get the job done correctly.

The vehicle doesn’t necessarily need to be washed prior to having a spray-in liner done, but it does help to have the vehicle clean. The shop handling the spray-in liner doesn’t want to have to deal with a dirty vehicle especially when they’re trying to tape off the vehicle and need the tape to properly adhere to the vehicle. Make sure you don’t wash the truck right before going to the shop because it may be just as bad dealing with a vehicle that may still be wet or retaining moisture.

Truck Bed Bolts

To spray over them or not to spray over the truck bed bolts? There’s a line drawn right down the middle separating those who say to spray over the truck bed bolts and others who say to remove the bolts before spraying. When you see a brand new truck that has had a spray-in liner done from the factory, it will usually be sprayed over the truck bed bolts. There are a lot of reasons for doing it one way or the other, but in the end you should consider these things:

- Potential corrosion? It may be an issue (in different ways) one way or the other. Spraying over will completely seal the bed (and bed bolts), until perhaps you have a heavy load somehow hitting the bolt heads and causing a gouge and a source of potential corrosion on the bolt itself. It is also possible if you remove the bolts, spray in the liner, and then tighten down the bolts again, that you might cause a potential source of water intrusion in the liner. Either way, it the potential for corrosion can be seen as minimal.

- Do you ever need to remove the bed of your truck? If you ever need to remove the bed of your truck for whatever reason, you will probably want the spray-in liner sprayed when the truck bed bolts are removed. This is due to the fact that spraying over the truck bed bolts will make it more difficult to fit the proper tools in the bolts to remove them. It’s still possible by chipping or cutting out the liner in and/or around the bolt head, but it’s a pain to deal with if you do plan to remove the truck bed in the future.

- Looks? This is personal preference, some like the entire truck bed fully covered with liner so that the entire bed is uniform in color, and some others like the look of the exposed bolt heads contrasting from the black liner.

- Concerned about fastening of truck bed bolts? Some bolts may be installed with thread lock, and some might be fastened in other ways that might be of concern when the bolts are removed. Some people complain that once it comes back from the spray-in bed liner shop, that the bed sounds/feels loose (perhaps due to incorrect re-installation). If you’re worried about this and don’t mind spraying over the truck bed bolts, then don’t have the shop remove the truck bed bolts. If you need access to the truck bed bolts in the future, just make sure that the shop is installing it correctly to avoid any future issues with your truck bed.

Brands of Spray-in Liner

There are a number of spray-in liners with Line-X and Rhino Linings being amongst the most popular ones. From what I have heard, Rhino spray-in liners tend to be a slightly softer texture than the Line-X. The consensus is that Line-X is usually one of the best liners you can get out there due to their reputation and amazing product. And because of that, the price is up there too. Keep in mind that with each brand however, there are different grades offered and so the final product can vary widely depending on the brand and the type of bed liner that you get sprayed on.

DIY Spray Kits

Quite a few DIY spray-in bed liner kits exist in the market with varying grades available for the consumers to spray-in their own bed liner. There are the average rattle-can sprays that are available such as Seymour, Herculiner, Duplicolor, Rustoleum, and more. These are the typical ones you might find at the local hardware or auto parts store, but also online. These are all generally the cheapest option and have varying levels of ineffectiveness. Some work slightly better than others with regards to UV protection, appearance over time, impact, and resistance to chemicals. But in the end, all of these options don’t produce very durable nor produce long-lasting results.

Of the spray kits available, there are options that are made of urethane that has better flexibility than the epoxy sprays. Although it retains flexibility better than epoxy, it does have less strength. One example of this is the U-Pol Raptor Spray-on Liner. This kit includes a spray gun and will require an air compressor to spray with. This type of spray-on liner will be better suited for the long term expansion and contraction that the bed will likely experience over its life.

If choosing the DIY route, be vigilant in your preparation and in your masking of the rest of your vehicle to prevent overspray. The spraying process is not the difficult part (although there are some spraying techniques that are necessary); it is the preparation of the bed and the proper masking off of the rest of the vehicle. Preparation is key to a successful spray-in bed liner.

Roll-on liners are also available as an alternative to spraying in the liner. Rolling on the liner may provide you with some benefits over the spray-in option such as ease of use (especially if you don’t have access to tools/equipment for spraying), less mess, and usually more economical. However, they don’t look as nice as spray-in liners and are harder to apply in certain corners and hard to reach areas.

Hybrid/Component Bed Liners

Hybrid or Component bed liners are multi-piece systems that may include a mix of different parts possibly made of different materials, which fit in the truck bed as a liner. One of the most popular ones is Dual Liner, which is composed of plastic sides and a rubber mat on the bottom. If you’re concerned about the pooling of water and debris between a drop-in liner and the truck bed, this might be a better option as the bed mat has nibs on the bottom, which Dual Liner says helps provide air flow to prevent corrosion.

This might also be a good option for those who are concerned about the installation process of spray-in bed liners, which involves the scuffing up of the clear coat on the bed of the truck. The hybrid/component bed liners are made specifically for any particular vehicle, so fitment should be quite good. There are some minor complaints of Dual Liners quality control so its possible to get one that fits perfectly, and others that have very slight gaps.

Cost of these hybrid bed liners are around $400 and the good thing about it is that you can order it and have it shipped to you. You can then install it yourself right away. This might be more desirable than having to wait for an appointment and then wait for the spray-in liner to be done, if you’re going the spray-in route. The other benefit of this type of liner is that the bottom portion of the component liner is a thick rubberized mat, and therefore it absorbs impact as well as sharp/blunt force better than spray-in liners.

Bedrug Bed Liners

Although the appearance will make you believe that Bedrug bed liners are some kind of carpet material, they are not. They are made of 100% polypropylene (essentially plastic) that helps protect the bed of the truck. These bed liners can be installed directly over a bare truck bed, or even over a spray-in or drop-in liner. The interesting thing about this material is that it has a closed-cell structure and is therefore 100% waterproof.

These bed liners come in several pieces, similar to the component or hybrid bed liners. The sides and bottom are connected via a heavy-duty zipper and the Bedrug is attached to the bed of the truck via sticky strips.

The pros of using this material is that it offers a plush material in the bed of your truck if you spend time there or if you have pets that will be in the back. It also does not cause the same rubbing issues as a drop-in liner might as polypropylene will not scratch the truck bed paint. Bedrug also helps keep things from sliding around in the trunk and is easily cleaned off as it does not mold/stain.

How to Pick the Right Bed Liner for your Needs

Many factors go into choosing the right truck bed liner for you and it’s important to look at each one to determine what best fits your needs. I made a table below that grades each bed liner option’s characteristics so that you get an idea of how each performs.

Keep in mind that this is purely subjective, so these grades are based upon my research and my ultimately my opinion about each of these bed liner options. This table might help give you an idea of how one bed liner performs better or worse relative to one another. If you want to pick the right bed liner for your truck bed, definitely read through the details on each type of bed liner and use this table as a supplement for making your decision.

| Bed Liner Type | Appearance | Durability | Chemical Resistance | Ease of Cleaning | Ease of Installation | Resistance to Spread Impact | Resistance to Concentrated Impact | Cost |

|---|---|---|---|---|---|---|---|---|

| Plastic Drop-in Bed Liner | C | B | B | B | C | A | B | $$ |

| Spray-in Liner (Shop Install) | A | B | B | B | A | B | C | $$$$ |

| DIY Spray-in Liner | C | D | D | C | F | D | D | $ |

| Hybrid Liner | B | B | D | C | B | A | B | $$$ |

| Bedrug Liner | A | B | B | C | B | A | B | $$$ |

| Spray-in Liner With Bed Mat | B | A | A | C | A | A | A | $$$$$ |